Concrete Slabs Built for Heavy-Use Spaces in Quincy Homes

Concrete Slab Quincy

In Quincy’s area, homeowners need heavy-duty slabs for their garages, workspaces, and outdoor spaces; this will give them a solid base for all of their vehicles, tools, and areas with high traffic. In addition to the potential heavy use, building the slab in a way that makes it long-lasting and safe for its intended use is very important due to the freeze-thaw cycle and other coastal factors that can weaken the concrete. This manual will cover how to build concrete slabs that are both durable and have a long life span, to help keep your heavy-use spaces both operational and safe for many years.

Quincy’s Severe Weather Conditions Require Heavy-Duty Concrete Slab Solutions

Garages, driveways, and workshops are all high-traffic spaces with heavy vehicle use and equipment operations. Due to this use, regular standard concrete slabs will probably not be able to withstand the repeated use and wear-and-tear, as well as the freeze-thaw cycle and salt damage associated with Quincy’s weather. It is therefore imperative to have heavy-duty reinforced concrete slabs to provide the necessary strength and durability to meet the demands of the use of these spaces.

Comparison of Standard vs. Heavy-Duty Slabs

Standard concrete slabs are approximately four inches in thickness and are sufficient for most residential use. However, heavy-duty slabs need to be thicker, have more reinforcement, and are made using high-strength mixtures to provide adequate support for vehicles and equipment. Furthermore, due to varying soil conditions and harsh weather conditions in Quincy, heavy-duty slabs provide a stable and long-lasting surface by preventing cracks and settling. Heavy-duty slabs are an absolute necessity for garages and workshops.

Characteristics of Heavy-Duty Concrete Slabs

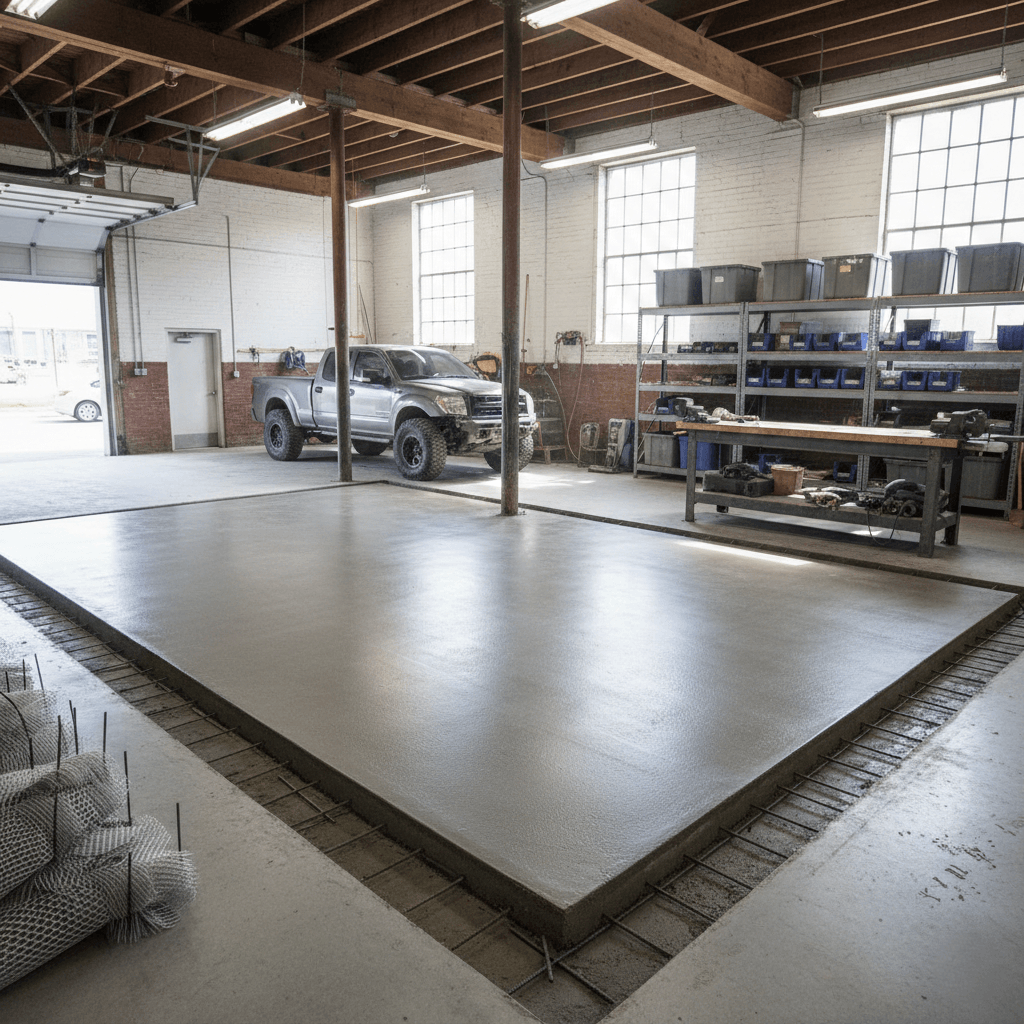

Heavy-duty concrete slabs are designed to increase the strength and durability of the slab by having several characteristics. First, the slabs are thicker than standard slabs, typically six inches or more, which helps to distribute the weight of the vehicle and equipment evenly and reduces the potential for cracks. Second, the slab contains steel rebar or fiber mesh reinforcement to help prevent the slab from bending or cracking when subjected to heavy loads. Third, the high-strength concrete mixture used has a compressive strength of four thousand psi or greater, which helps to improve the overall durability of the slab and makes the heavy-duty slab ideal for Quincy’s harsh weather conditions.

Thickness and Reinforcement

The minimum thickness for heavy-duty slabs is six inches; however, the thickness may need to be increased to eight inches or more for some uses. Additionally, the slab contains reinforcement, either steel rebar or synthetic fibers, to help resist cracking and shifting. In Quincy, where there is considerable soil movement and freeze-thaw cycles, the reinforcement in the slab will also help maintain the stability and integrity of the slab.

High-Strength Concrete Mixes

High-strength concrete mixes, which have a compressive strength of four thousand psi or greater, are critical to the construction of heavy-duty slabs. The high-strength mix contains more cement and aggregate than standard concrete mixes, which increases the load-bearing capacity of the slab. In Quincy, where salt and moisture cause accelerated wear, high-strength concrete resists erosion and will maintain the slab’s integrity for decades. Contractors frequently recommend high-strength concrete mixes for garages, driveways, and workshops, where durability is a primary concern.

Best Installation Practices for Quincy Slabs

In order to ensure the success of a heavy-duty concrete slab, proper installation is critical. The first step in the installation process is site preparation, which includes excavating the area, leveling, and compacting the soil to prepare a solid base for the slab. A four-inch layer of gravel or crushed stone should be placed between the slab and the base to allow for good drainage and to minimize the potential for settling. In Quincy, where the soil can be unstable and there are many freeze-thaw cycles, preparing a solid subbase will ensure that the slab is level and crack-free.

Preparation of the Site and Subbase

First, the site should be excavated down to the desired depth to accommodate the slab thickness and the subbase. Then the soil should be graded so that it drains properly and slopes away from the surrounding structure. Once the soil has been graded, it should be compacted to prevent settling. A four-inch layer of gravel or crushed stone should be added on top of the compacted soil to form the subbase. The subbase serves as a stable base for the slab and minimizes the possibility of the slab developing cracks or shifting due to the freeze-thaw cycles experienced in Quincy.

Pouring and Curing

To prevent cold joints, which can reduce the strength of the slab, the entire slab should be poured in one uninterrupted pour. Vibrators should be used to remove air pockets and achieve a uniform density of the slab. Following the pour, the slab should be cured for a minimum of seven days, with the slab remaining damp to prevent cracking. In Quincy’s climate, proper curing is vital to providing the slab with its full strength and durability.

Maintenance of Heavy-Duty Concrete Slabs

Heavy-duty slabs require very little maintenance, but occasional cleaning and sealing will extend the life of the slab. The surface should be swept clear of debris regularly and cleaned with a mild soap and water solution. Sealants should be applied to the slab every two to three years to protect against moisture, salt, and UV degradation. In addition, prompt snow removal and the use of gentle deicing products during winter months will help to prevent damage to the surface of the slab, thus maintaining the functionality and safety of the slab in Quincy’s harsh winters.

Seasonal Care for Heavy-Duty Slabs

Prior to each season, inspect the slab for any cracks or signs of wear. Any minor damage to the slab should be repaired immediately to prevent the damage from progressing. During the winter months, refrain from using harsh deicers that can damage the surface of the slab. Instead, use sand or calcium magnesium acetate for traction. Practicing these seasonal care tips will help maintain the optimal performance of the heavy-duty slab throughout the year in Quincy’s severe climate.

Selecting a Contractor for Heavy-Duty Slabs

A qualified contractor will ensure that your heavy-duty slab is constructed to meet the stringent standards of quality and durability for Quincy. Consider contractors who have extensive experience installing commercial-grade concrete. Request references and examples of previous jobs, specifically jobs that involved garages, driveways, or workshops. A reputable contractor will provide you with a comprehensive estimate, describe the installation process, and provide a warranty for their work.

Questions to Ask Before Hiring a Contractor

Before hiring a contractor, inquire about the contractor’s experience with heavy-duty slabs in Quincy. Does the contractor utilize high-strength concrete mixes and reinforcement in their heavy-duty slabs? What type of subbase does the contractor recommend for the variable soil conditions found in Quincy? How would the contractor handle any unforeseen problems, such as poor drainage or extreme weather? The contractor’s responses to these questions will help determine if the contractor is knowledgeable and committed to constructing a slab that will endure for decades.

Cost and Long-Term Benefits

While heavy-duty slabs are more expensive than standard slabs, they provide significant long-term benefits. Prices for heavy-duty slabs typically range from eight to fifteen dollars per square foot, based on the thickness of the slab, the amount of reinforcement, and any finishing coats. Calculate the long-term cost savings resulting from reduced maintenance and repair costs over the life of the slab. As a result of the increased durability and load-bearing capacity of heavy-duty slabs, many Quincy homeowners feel that the upfront investment is justified, especially for high-traffic areas.

Estimating Costs for Your Project

Obtain quotes from licensed contractors to compare prices and services. Some contractors offer financing options or discounts for large projects, which can make it possible to invest in a high-quality slab. When selecting a contractor, prioritize both durability and craftsmanship to ensure that your heavy-duty slab is functional and adds value to your home for decades to come.

Final Thoughts: Creating Slabs for Heavy Traffic

Heavy-duty concrete slabs are a crucial component of any Quincy home that has a garage, workshop, or other high-traffic space. With the right materials and installation techniques, along with a reputable contractor, you can build a strong and durable slab that will withstand the day-to-day wear-and-tear associated with heavy traffic. At Quincy Solid Concrete, we have years of experience designing and building slabs that are specifically engineered to meet the demands of our community.