Concrete Slabs in Quincy, MA

Durable Concrete Slab Installation in Quincy, MA

Every building or construction project requires a strong base, and concrete slabs are just that. At Quincy Solid Concrete, we pour numerous concrete slabs to meet many different applications, from garden sheds to garage floors, hot tubs to house additions, etc. With all of our concrete slab contractors using a combination of precision engineered and high-quality craftsmanship in every installation we do, we will design each slab for the particular application it will be used for, considering factors including, but not limited to, the load bearing capacity required for the slab, the need for drainage with the slab, and the type of soil present at the location where the slab is being poured.

Get A Free Quote

What is a Concrete Slab?

A concrete slab is an essentially flat horizontal plane of solidified concrete used in construction projects as a base, a floor, or a roof.

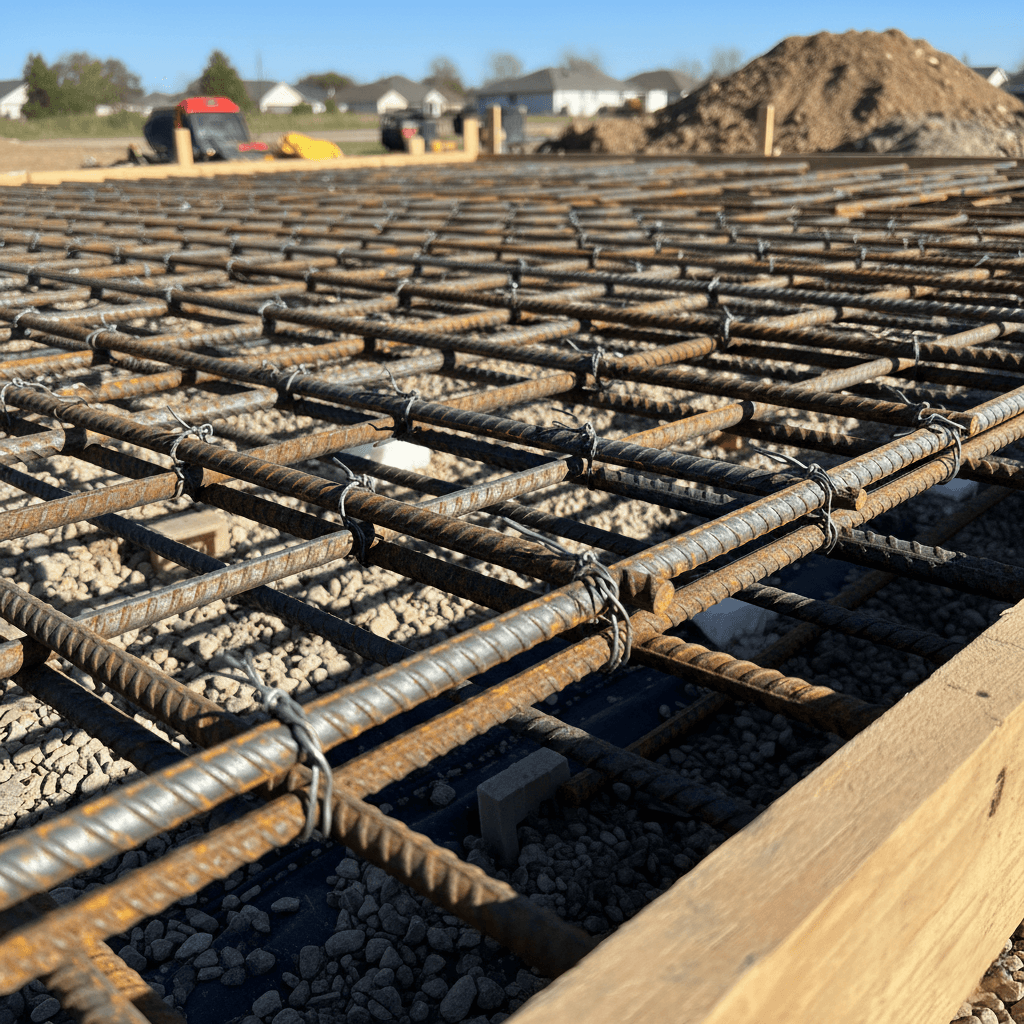

The function of the concrete slab is to provide a uniform distribution of weight onto the earth’s surface to reduce stress on the surrounding soil, to protect against water and/or moisture penetrating the structure (e.g., garage), and to create a smooth level surface. The thickness of a concrete slab will depend upon its application (i.e., what it will be supporting) — typically, a 4-inch thick slab would be sufficient to support lightweight conditions (e.g., a residential floor), whereas a minimum of 6 inches of thickness is required to support heavier structural loads (e.g., commercial buildings). To minimize the effects of cracking and to extend the life of the concrete slab, we embed reinforcement materials such as steel rebar or wire mesh.

Concrete Slab Design Options

Concrete slab design depends on your project’s requirements. We offer several configurations:

Standard Flat Slab: A simple and cost-effective option that will meet the needs of a large portion of residential jobs.

Thickened-Edge Slab: This type of design provides added reinforcement to the perimeter, which will help support heavy structures.

Monolithic Slab: One pour for both the foundation and the floor – great for projects where time and money are important.

Post-Tensioned Slab: Steel cable under tension helps with heavier loads over longer distances as well as in areas with poor soil conditions.

Concrete Slab Applications

Around Your Home: A Clean Edge

A concrete slab around your home gives you a clean edge (around your home) and is a low-maintenance solution. It also keeps plants from growing up against your home and helps improve drainage. Plus, it is an ideal spot for setting up outside furniture and other equipment. We make sure to pitch your slab away from your home so that all water flows away from your home properly. A lot of people like to use the space around their homes as an additional room in their homes. Whether you choose to do that, we know you will enjoy the space around your home.

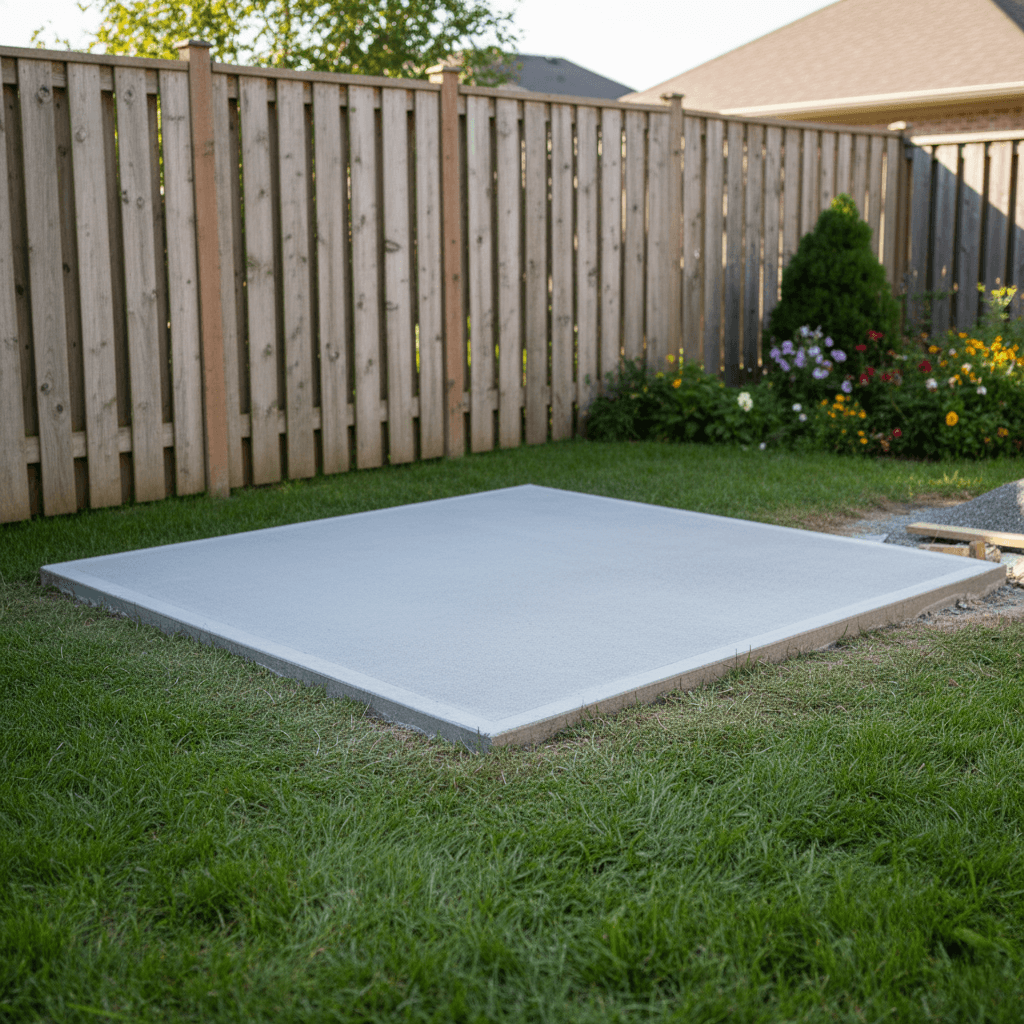

For Your Garden Shed: A Proper Foundation

If you have a garden shed, you want a solid foundation underneath it. That’s why we build a proper concrete slab for garden sheds. We ensure that your shed will be level, prevent moisture from damaging your shed, and eliminate any settlement issues. With a good, solid slab under your shed, your shed will last longer, and the floor of your shed will stay dry and free of pest problems. We can build the slab to match the exact measurements of your shed or extend the slab out about one foot to give you some space to set up a small work area.

For Around Your Pool: Specialized Work

When working around a swimming pool, you need specialized concrete work. Our concrete slabs for around pools handle constant water exposure and provide a safe, slip-resistant surface. We plan the drainage properly to make sure water doesn’t accumulate on your concrete. We make sure our concrete has enough thickness to hold pool equipment, furniture, and the foot traffic around your pool. And depending on what look you want for your concrete, we can finish it with a broom texture for better traction, or a stamped finish for a decorative look.

For Your Shed: An Ideal Space For Storage

Do you store lawn equipment? Do you have a shop where you build projects, or do you just have a place to put things you don’t want in your house? If so, a concrete slab for your shed is the perfect way to get the most functionality out of your space. We dig down to the right depth, install a compacted layer of gravel to help with drainage, and then pour a reinforced slab that will never settle or move. After we’re done, you’ll have a perfectly level floor that will protect your belongings from the ground and allow you to get the most function out of your shed.

Garage Floor Slabs: Made To Last

Garage floors take a beating. They have to withstand the weight of cars, extreme temperatures, and harsh chemicals. Our garage floor slabs are made to withstand these stresses. We pour them 5-6 inches thick with proper reinforcement and install control joints to help manage cracking. The result is a smooth, even surface that makes parking easy and creates a nice, clean workspace. We can apply a textured finish to make the surface non-slippery or prepare it for epoxy coating.

Our Concrete Slab Installation Process

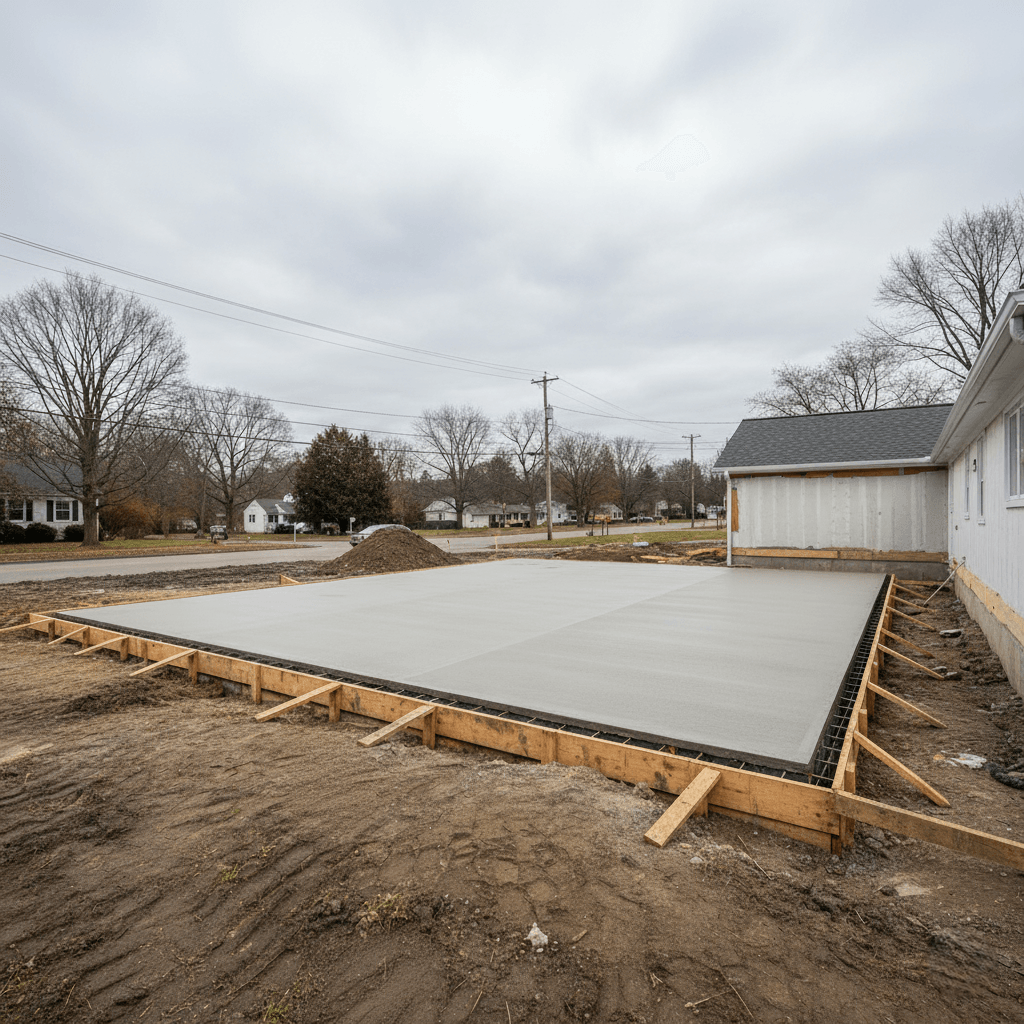

Quality concrete slabs start with proper preparation:

Site Evaluation: We evaluate the overall condition of the soil beneath the proposed slab area as well as the existing drainage system in order to determine the most suitable way to proceed.

Excavation: The excavation of the slab area to the specified depth allows us to remove the unsuitable soils that would be detrimental to the structural integrity of the slab, and will allow us to achieve the required grade.

Base Preparation: Providing a compacted base layer of gravel creates a void space between the base layer and the bottom of the slab, allowing water to drain away from the slab and preventing it from settling over time.

Form Setting: The precise setting of the forms assures that your slab will have the exact dimensions and configuration you need.

Reinforcement: The installation of rebar (reinforcing steel) or wire mesh provides the necessary strength to the slab to resist cracking due to settlement and/or traffic loads.

Concrete Pouring: Once the forms are set and the reinforcement is installed, we can now pour the concrete, spread it evenly across the slab, and bring the slab to the desired finished height.

Finishing: We then take the freshly poured concrete and smooth out the top to create a uniform surface, and then apply your selected finish.

Curing: Finally, by properly curing the concrete, we ensure that the concrete develops to its maximum compressive strength.

Why Choose Our Concrete Slab Contractors?

We are experienced concrete slab contractors near you in Quincy, MA, and know that every slab will be used differently. A hot tub slab is going to have different requirements than a shed foundation, so we design and build each installation based on how it’s going to be used, taking into account the loads involved, drainage needed, and local conditions as well.

As we’ve worked with concrete in Massachusetts, we understand how the weather can impact it, so we use concrete mixes designed for freeze/thaw resistance, and we make sure there is adequate drainage to keep water from causing problems. We are fully licensed, fully insured, and committed to doing quality work that will last.

Throughout your entire project, we will provide you with clear communication regarding what we are going to do and why, along with clear pricing and realistic time frames for completion of your project.

Ready for Your Concrete Slab Project?

Contact Quincy Solid Concrete today for a free consultation and detailed quote. Whether you need a small slab for a shed or a large garage floor, we have the expertise to deliver quality results. Let’s discuss your project requirements and create a concrete slab that serves you well for years to come.